Multi speaker system for audiology lab

This is another project I did as a part of my civil service. The following requirements had to be met:

- A linear actuator implementation to allow a non independent motion of each speaker

- Two separate motion directions

- Position accuracy of 1°

- Repeatability of loudspeaker positioning

- Tiltable frame

- Total cost of all mechanical parts 3000 CHF (excluding labour)

The reason behind this project: (Text mostly from W.Wimmer)

Link: ARTORG Hearing Research Laboratory

Motivation

Since its integration in 2011, the audiology laboratory of the ARTORG/Inselspital has extensively been used for clinical research projects. The laboratory equipment has been applied in more than 10 clinical studies. In addition, the test system has been used to answer specific questions in clinical cases (e.g. sound localization ability, speech intelligibility in noise).

Over the last years, the system software and hardware has constantly been extended. A miniature speaker array for minimum audible angle measurements and control software were added. Furthermore, the number of simultaneously usable channels was increased to 4, allowing for speech intelligibility in multi noise experiments. However, as new research questions appear, the current test system is reaching its limits. One example is the evaluation of complex signal processing algorithms (e.g., adaptive beam formers) in modern hearing aids or implant audio processors.

Existing laboratory

The existing laboratory is located in the ARTORG Center (Room C 208-3) within an audiometry chamber (6.0 x 4.1 x 2.2 m3). The chamber was certified for audiological testing in November 2012 (Diatec AG certificate No. HPK-A04 059). The audiological test equipment consists of a multi speaker setup with 12 speakers for sound field measurements and a miniature speaker array for localization tasks.

A custom-developed software is used to control the test setup. The software can be used to conduct the tests and automatically generates reports for archiving. The following tests/experiments are currently implemented:

- Speech intelligibility in quiet (Freiburger Einsilber/Zahlen)

- Speech intelligibility in noise (automated OLSA, normal or adaptive, single noise or multi noise)

- Localization tests (horizontal, 30° resolution)

- Minimum audible angle (frontal direction, 1.5° resolution)

- Center localization task (1.5° resolution)

Current limitations and possible improvements

- The OTL equipment (including a large table) influences the room characteristics because of large reflecting areas. At the moment sheets are put over the equipment to get a reproducible situation during studies. As the table will be removed, additional lab space is gained that could be used for new test systems (e.g. neurotology chair)

- The maximum number of channels for the multi speaker set up is currently limited to 4, because of hardware limitations. The amplifier/multiplexer unit enables to switch the 4 channels to the 12 speakers, however, a long switching time (0.5 s) limits the applicability for experiments. An increase of the number of available channels could be used to improve the experiment quality (e.g., more diffuse sound field for noise or virtual sound sources)

- The loud speakers are currently positioned with fixed stands (see Fig. 2). This has several drawbacks: (1) it is not possible to rearrange the speaker positions in reasonable time, (2) the closest distance between 2 speakers is limited to about 30° because of the floor stands, (3) the calibrated position of the speakers can be easily moved by other people, and (4) the positions of the speakers cannot be changed during an experiment only allowing static test conditions. A different fixation method as described in this concept can overcome these drawbacks.

Part 1: Extension of the multi speaker system

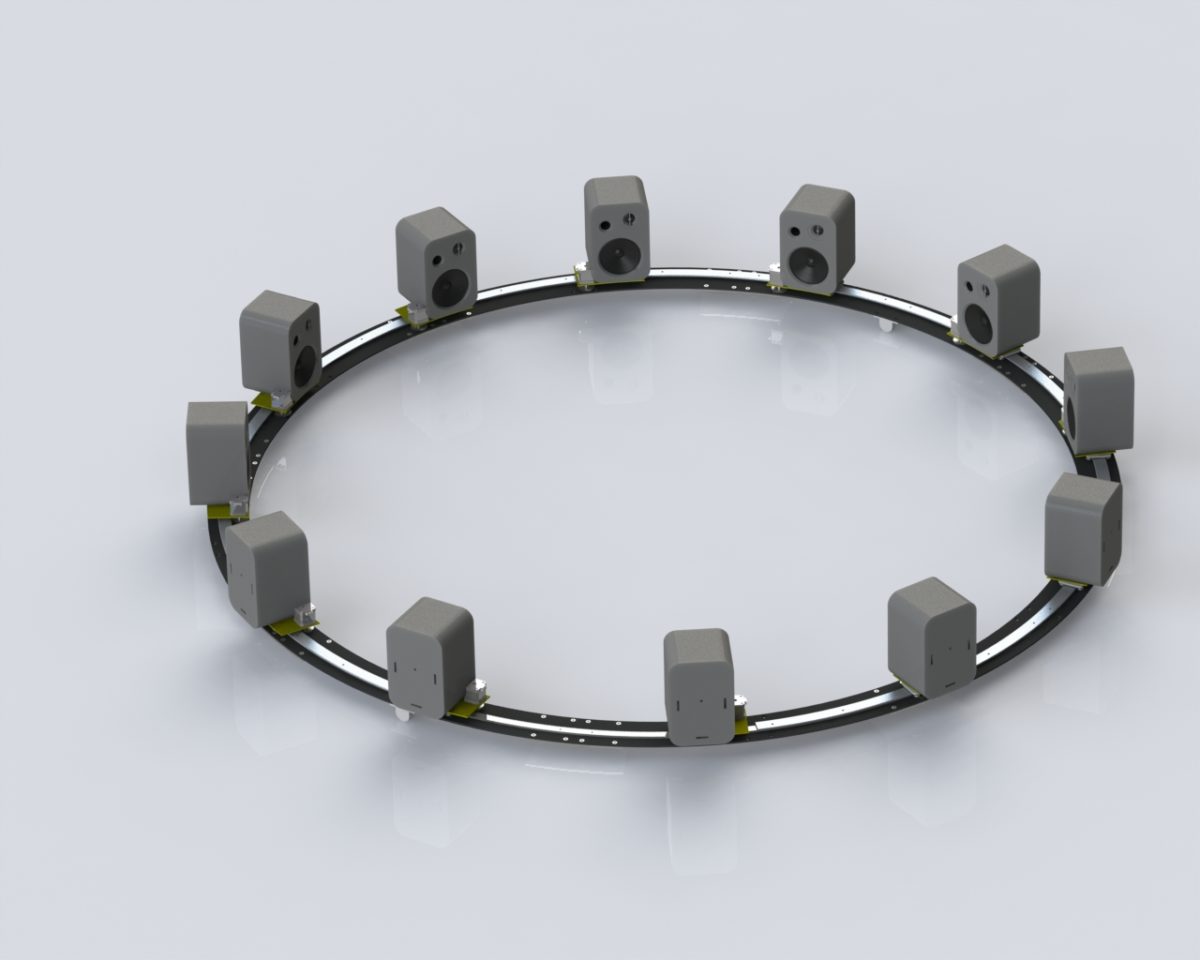

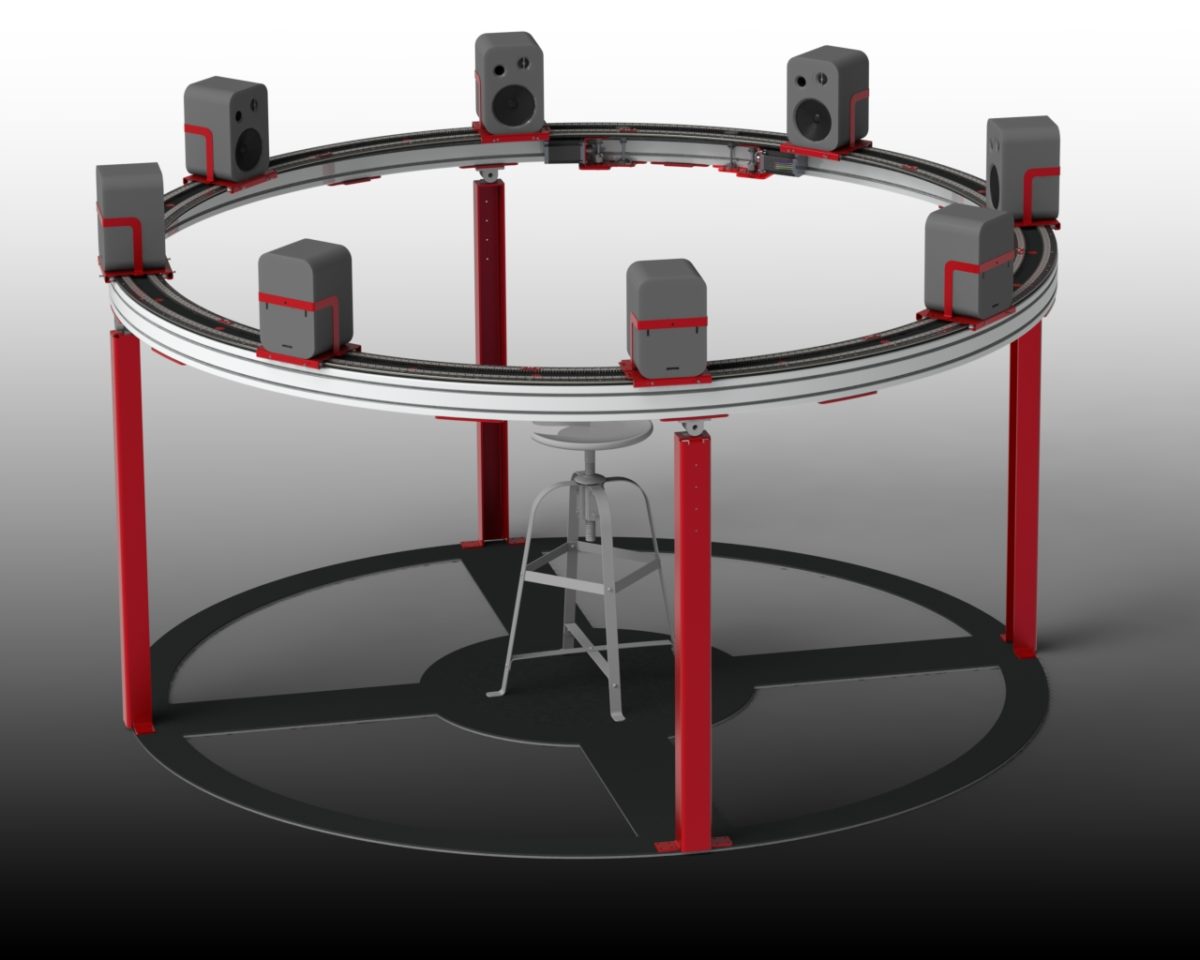

Figure 3 shows a rendering of the intended multi speaker setup upgrade. The concept is separated in 3 expansion levels, which are based on eachother.

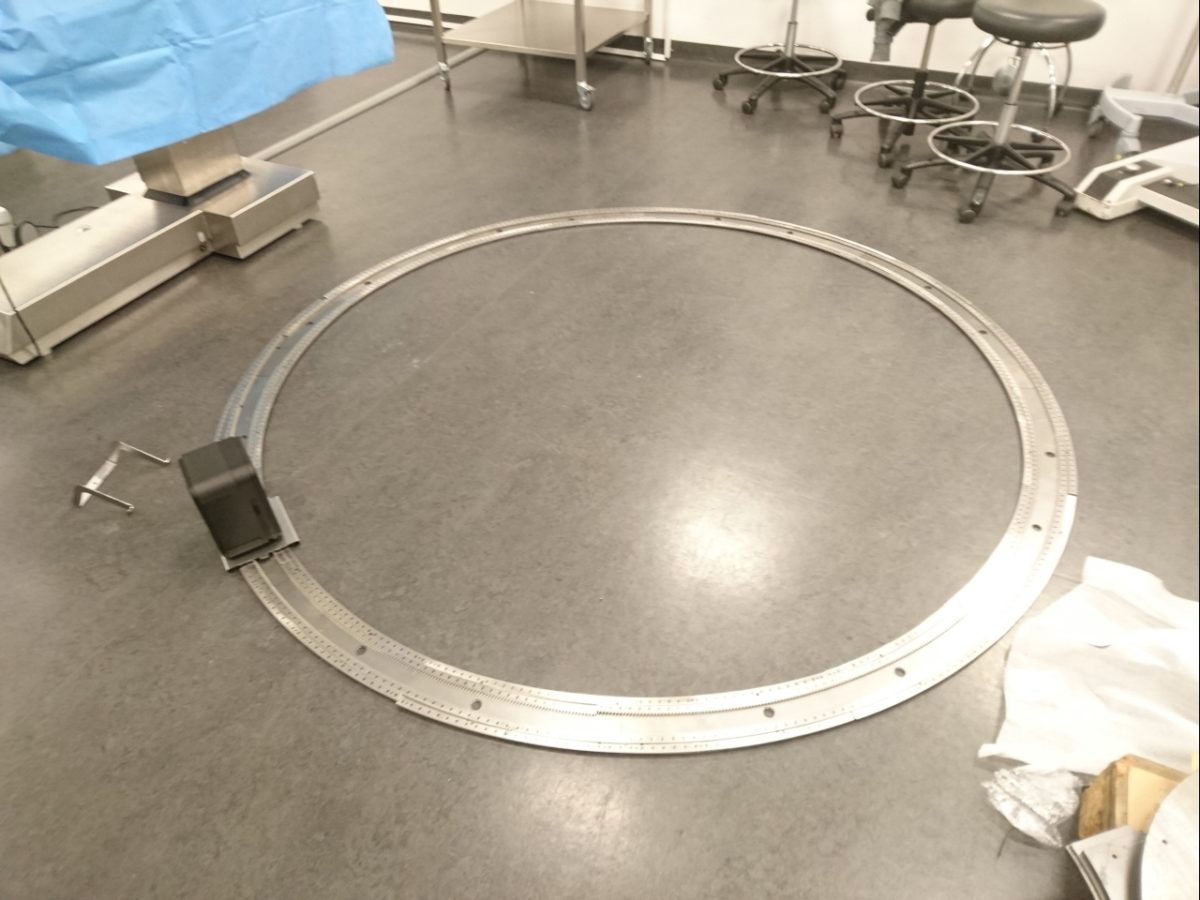

The first expansion level covers the production of a solid support ring with rails. On the ring, the 12 speakers are placed on slides allowing to position the speakers in arbitrary configurations at defined points. The whole ring can be pivoted to let the subjects enter the center of the ring, but also to allow measurements in the median plane. In addition, a ground plate with a grid is produced to enable for an exact positioning of the subjects or test/calibration equipment.

The second expansion stage is intended to increase the number of simultaneously usable audio channels from 4 to 16 (12 for the loud speakers and 4 spare channels). To gain this number of channels, new hardware components have to be purchased and installed.

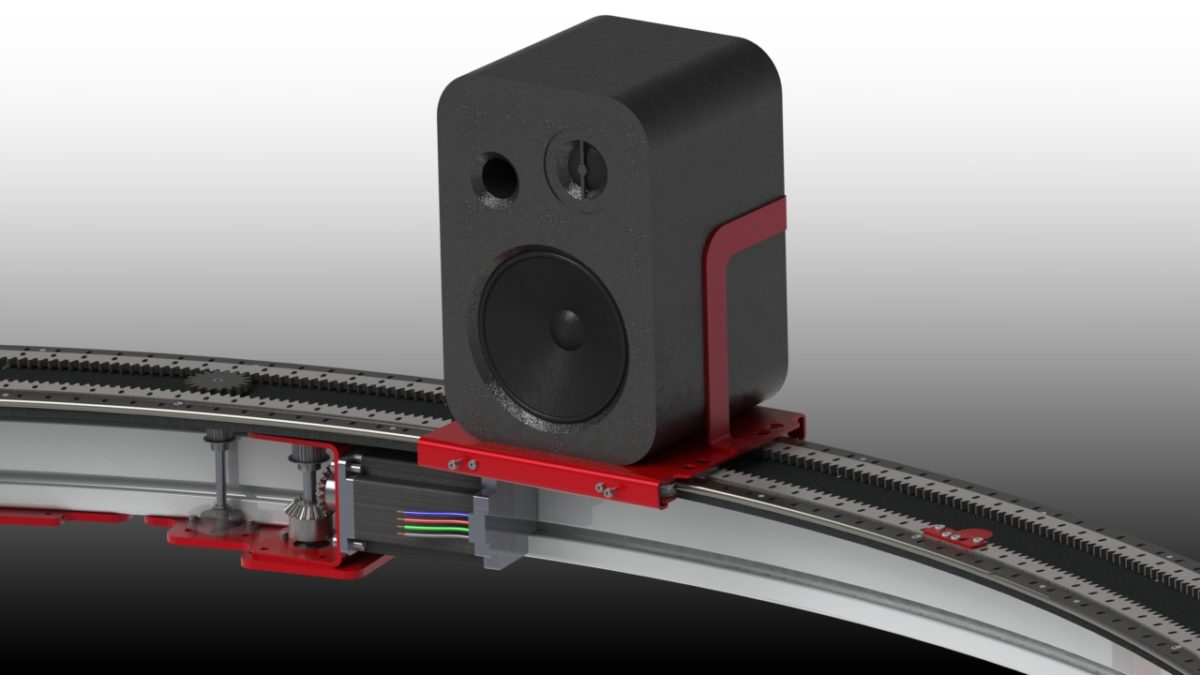

The third expansion stage will enable for an automatic positioning of the loud speakers on the rail. The slides with the speakers can be moved using step motors. The mechanics are designed to produce low noise during movement. This stage includes the installation of step motors, drivers and control units as well as the development of a dedicated control software. The control is intended to be implemented via a wireless connection (e.g. Bluetooth). In addition an external subject control device (e.g. tablet) will be included to allow for direct feedback of the tested subjects during the tests.

Benefits and advantages of the new system

After a full extension, the setup will allow for dynamic audiological tests and experiments. The system has the following advantages:

- Defined but flexible loud-speaker positions

- Defined reference point and grid for additional test equipment (e.g., chairs, panels, etc.)

- Easier entry to the multi speaker set up

- Pivoted ring for measurements in the median plane

- Simple, automatic calibration of the system is possible

- Simple, automatic measurement of directional patterns possible

- 16 simultaneously available audio channels

- Simple control of audio channels with single sound card

The following experiments/tests can be envisioned:

- Dynamic speech in multi noise tests (e.g. moving noise sources for adaptive beam formers)

- Minimum audible angle in arbitrary directions with resolutions of less than 1°

- Adaptive sound localization tests

- Sound localization in arbitrary configurations (e.g., 12 speakers in the frontal semicircle)

- Audiological tests with moving sound sources

- Subject-controlled (self-controlled) experiments

Design

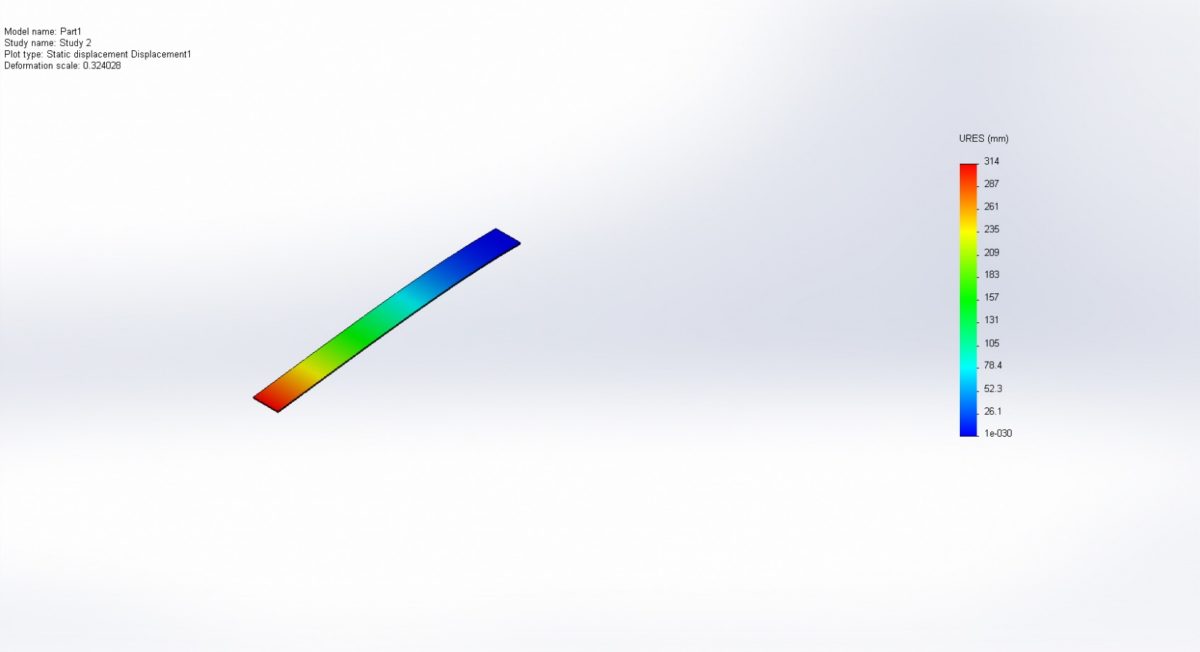

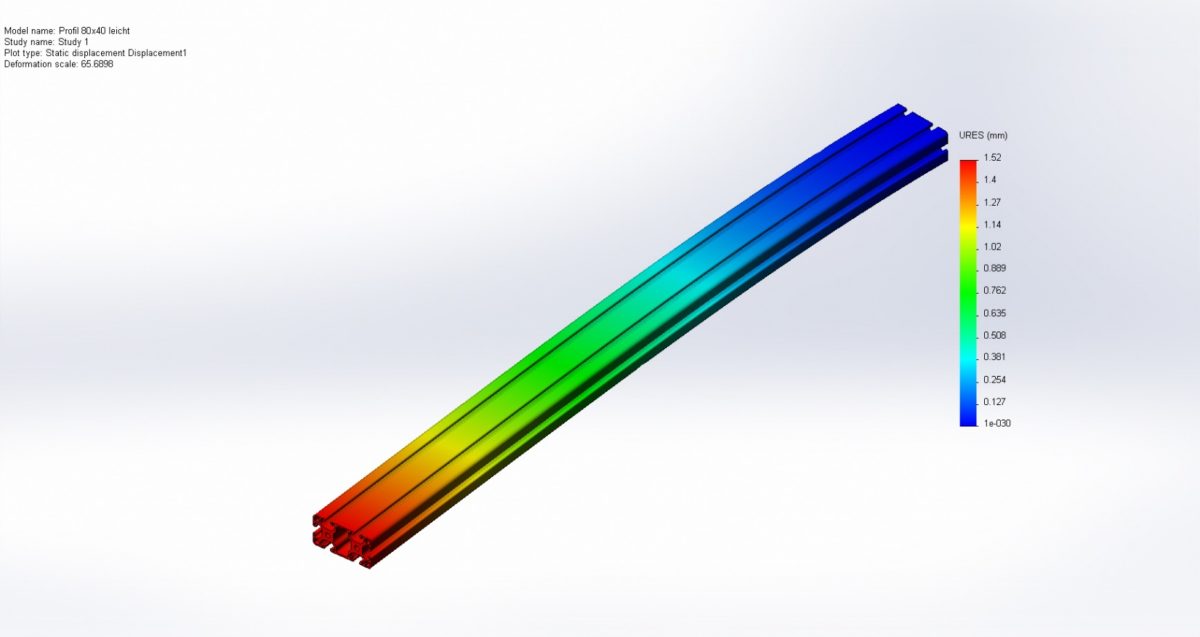

The static analysis showed quickly that the rig from the figure above wouldn’t be stable enough.

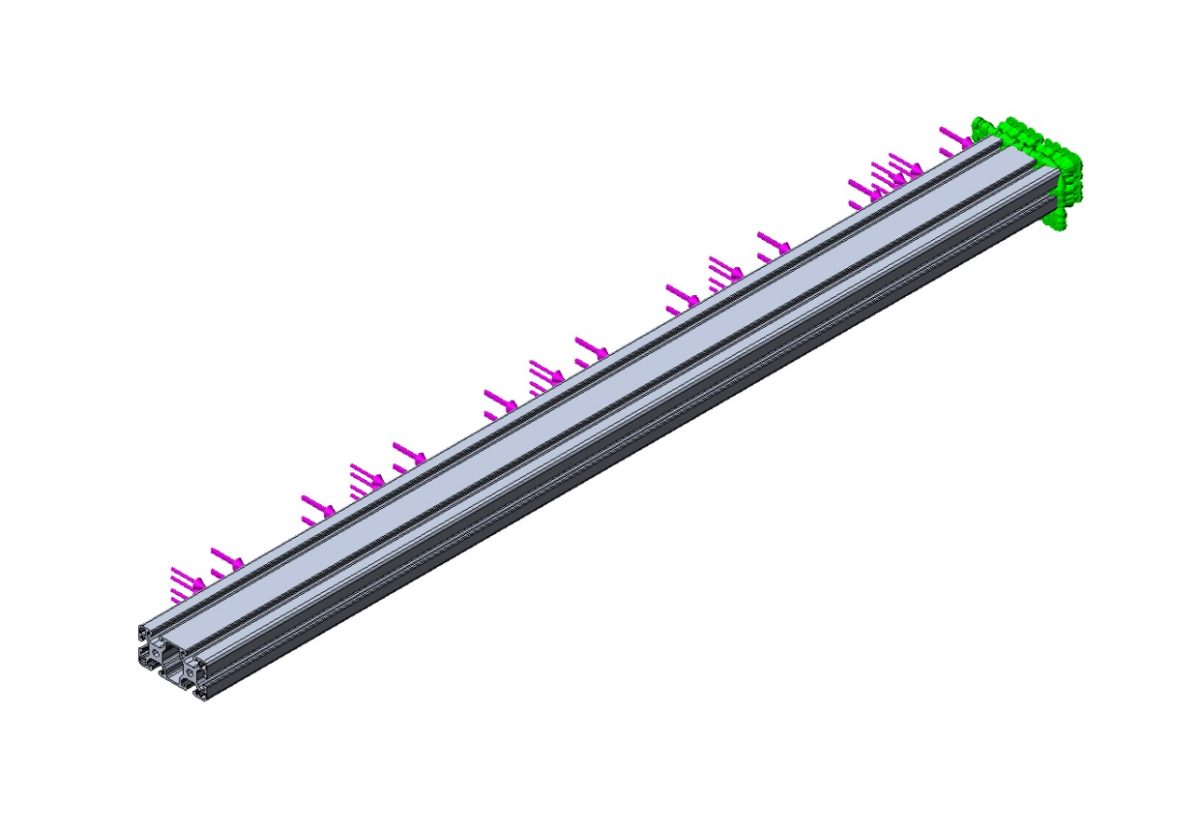

Therefore a better support structure had to be taken into consideration. In the end the decision was made to use a custom bent aluminium structure to support the rails. The analysis showed that the maximum displacement if only held by the bolts on the two pivot points would be less than two millimeters. To simplify the simulation it was done with straight aluminium structures and only from one side. So the end product would will be even more stable than the simulation assumed.

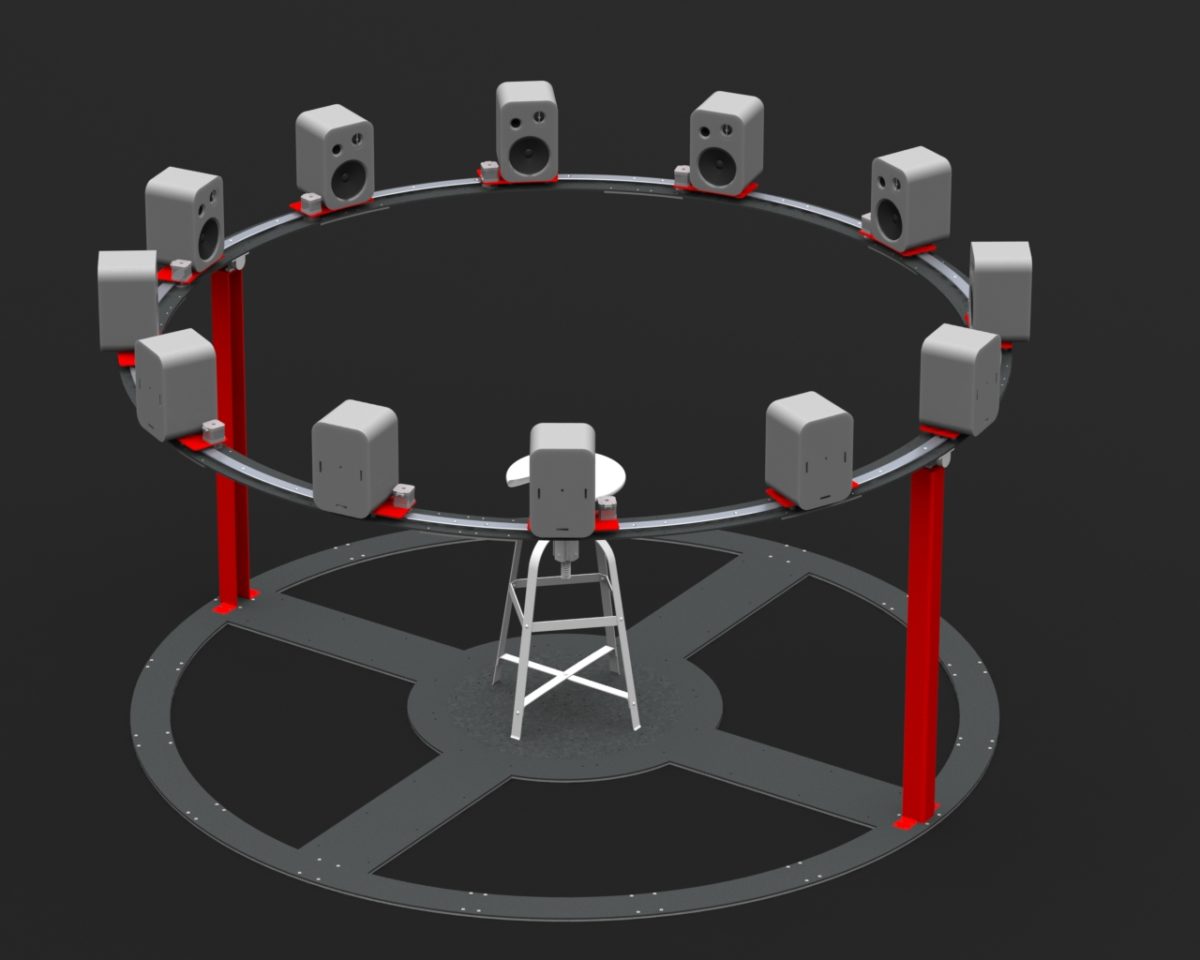

The following figure shows the design of the final system. We later ran into some problems with the design but nothing that couldn’t be solved. But more on that later. The aluminium support structure is fixed on four legs. Two legs can be removed so that the whole ring can be pivoted in order to make measurements in the median plane.

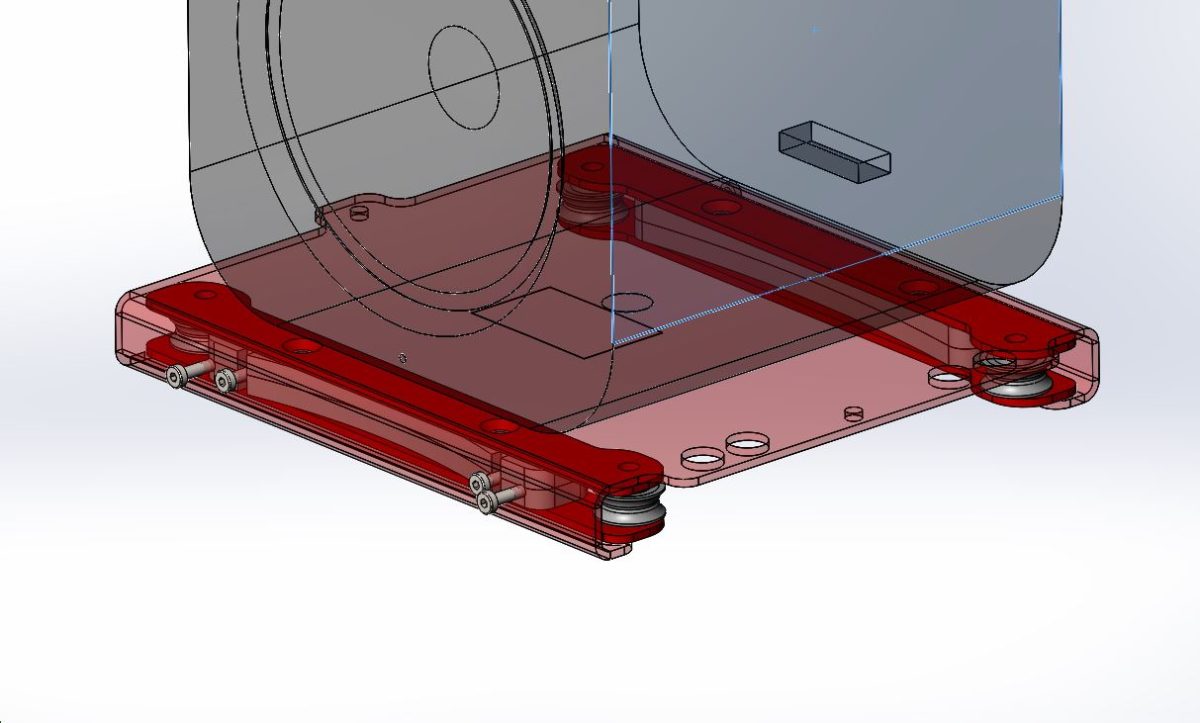

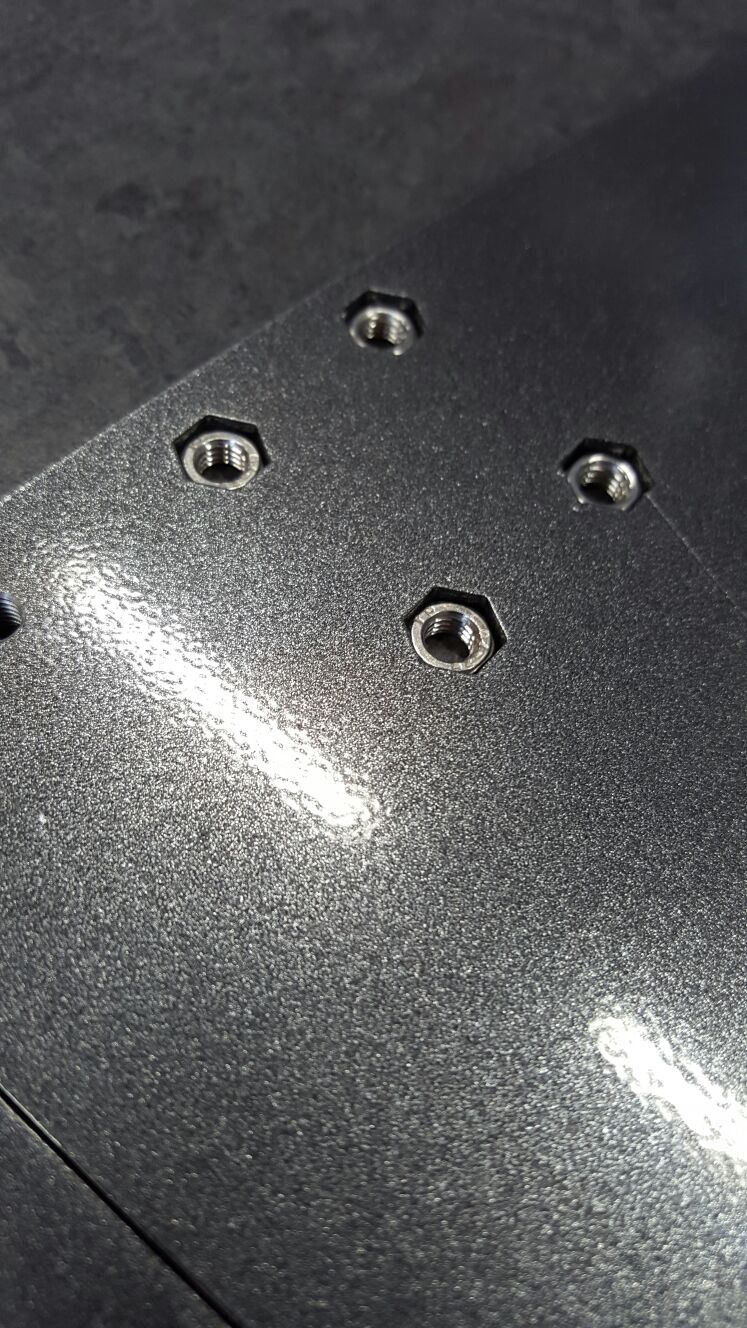

Each loudspeaker is mounted on a low profile wagon with four u-bearings that keep it on the rail.

Implementation

After we were finally confident with the design, we had to bring the design from paper into reality. Since my time there was absolutely limited (From the start of the design to building the rig I only had around two months.) I quickly began to order all the parts. Most mechanical parts like bearings came from china. The sheet metal parts as well as the aluminium support structure were ordered in Switzerland. I could still get access to the powder coating machine of my former workplace. In a two-day session we painted all the parts and soon after started to assemble the rig.

Unfortunately I couldn’t finish since my civil service ended, but I got some pictures that W.Wimmer sent me.

So here’s the semi final product. The loudspeakers are individually moveable but no yet motorized. This will be implemented in the next step but some efforts have already been made.

Hi, my name is Zijian Huang, a phd student from Tsinghua University, Beijing. I am interested in your speaker system with related to the spatial hearing and hope to construct it in my lab. Could you please introduce me some experience of how to design it cause it seems complex and I don’t have any engineering background?

Hi Zijiang,

You can write to the contact below. If he agrees, I can release the source files if you want…

https://www.artorg.unibe.ch/research/hrl/index_eng.html

Experience you get by doing things yourself. I am sure you will find someone suitable in your University who can help in your endeavour.

Cheers

Got it. Much thanks.